About Us

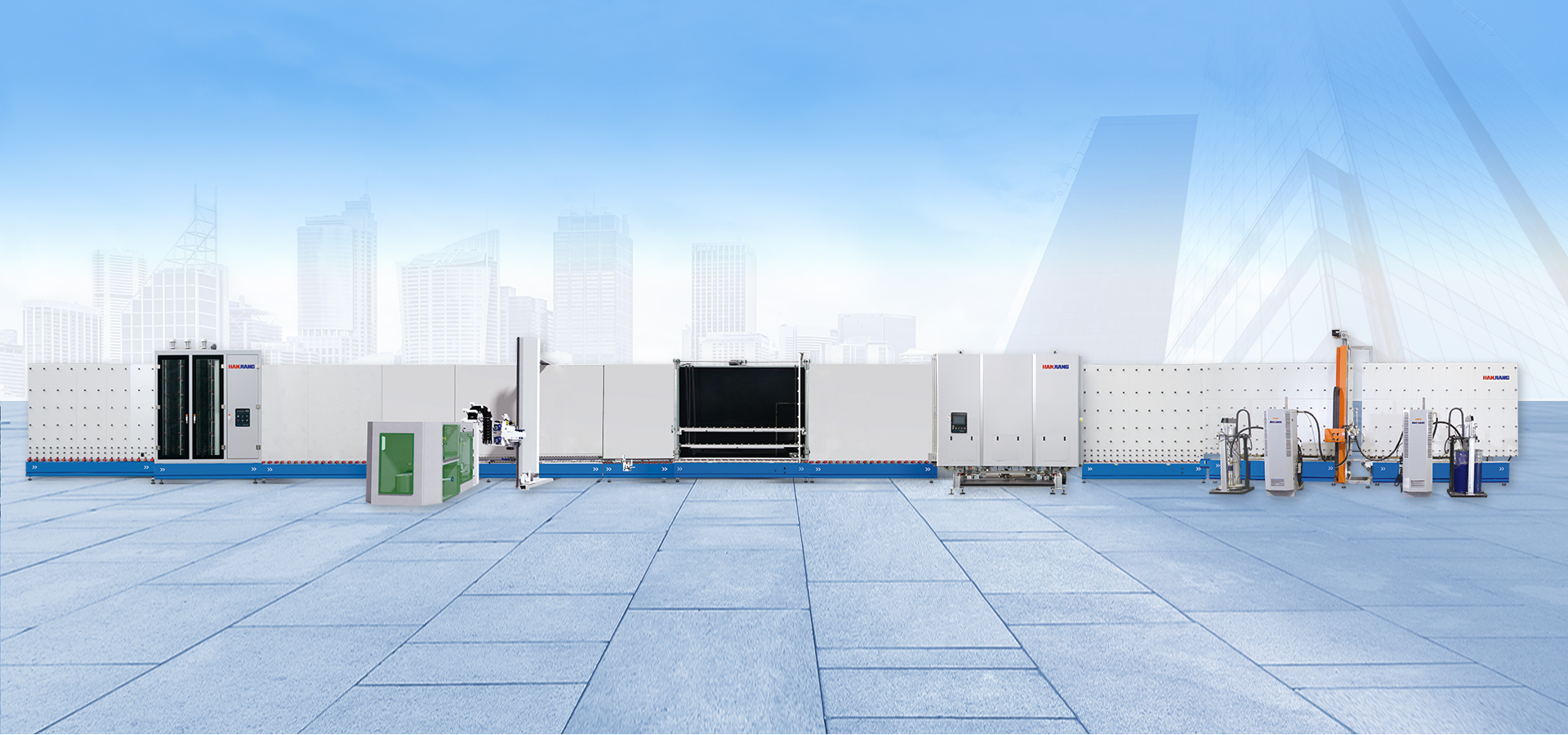

Hanjiang is manufacture of automatic IG production line, double glass processing equipment for insulated glass and double glass.

Major products cover Automatic Insulated Glass Processing Line, Warm Edge Spacer-Super Spacer Applicator and Thermo Plastic Spacer-TPS, Vertical Glass Washing Machine, Vertical Glass Seaming Machine, Horizontal Glass Seaming Machine, Automatic Glass Loading Machine, Low-E Glass Film Removing Machine, Insulated Glass Sealing Robot, Automatic Aluminum Spacer Bending Machine/Ragid Spacer Bending Machine, Desiccant Automatic Filling Machine, Two Component Sealants Extruder/Silicon Pump, Automatic Butyl Extruder, Automatic Cork Pad Applicator and other IG, Insulated Glass or double glass processing auxiliary machine and equipment.

Since promoted to the market, its products are warmly received by the domestic and overseas customers.

Till now, Hanjiang has been installed more than 3600 sets of full automatic IG line in more than 80 countries all over the world.

Hanjiang won more than 30 national patent certificates. Its products passed authorized products certification, such as CE,UL, CSA, SABER certifications.

As a glass machinery manufacturer, we devote ourselves to products quality. Our advanced technology, high quality products and reliable service bring insulated glass processors much convenience.